What is EII?¶

Introduction to Edge Insights for Industrial¶

Note

Edge Video Analytics Microservice (EVAM), is now the default Video analytics pipeline. It is recommended to use EVAM instead of VideoIngestion(VI) and VideoAnalytics(VA).

Since its inception in early 2018, EII has been focused on enabling the rapid deployment of solutions aimed at finding and revealing insights on compute devices outside data centers. The title of the software itself alludes to its intended purposes:

Edge :- systems existing outside of a data center.

Insights :- understanding relationships.

This software consists of a set of pre-integrated ingredients optimized for Intel® architecture. It includes modules that enable data collection, storage, and analytics for both time-series and video data, as well as the ability to act on these insights by sending downstream commands to tools or devices. To learn more about the EII v4.0.0 key features and improvements, refer to the Release Notes.

This guide will detail the capabilities of EII ingredients and will serve as a reference for developers working with them. This guide is designed to enable developers to create custom solutions for their end customers.

Overview¶

By way of analogy, Edge Insights for Industrial (EII) includes both northbound and southbound data connections. As shown in Figure 1, supervisory applications, such as Manufacturing Execution Systems (MES), or Work In Progress (WIP) management systems, Deep Learning Training Systems, and the cloud (whether on premise or in a data center) make northbound connections to the Edge Insights for Industrial. Southbound connections from the Edge Insights for Industrial are typically made to IoT devices, such as a programmable logic controller (PLC), camera, or other sensors and actuators.

The typology of the northbound relationship with MES, WIP management systems, or cloud applications is typically a star or hub and spoke shaped, meaning that multiple Edge Insight nodes communicate with one or more of these supervisory systems.

Incremental learning, for example, takes full advantage of this northbound relationship. In solutions that leverage deep learning, offline learning is necessary to fine-tune, or to continuously improve the algorithm. This can be done by sending the Insight results to an on premise or cloud-based training framework, and periodically retraining the model with the full dataset, and then updating the model on the Edge Insights for Industrial. Figure 1 provides an example of this sequence.

Note

It is important to use the full dataset, including the original data used during initial training of the model; otherwise, the model may over-fit. For more information on model development best practices, please see https://software.intel.com/en-us/ai/courses/machine-learning

Figure 1. Northbound and Southbound Destinations¶

High Level Architecture¶

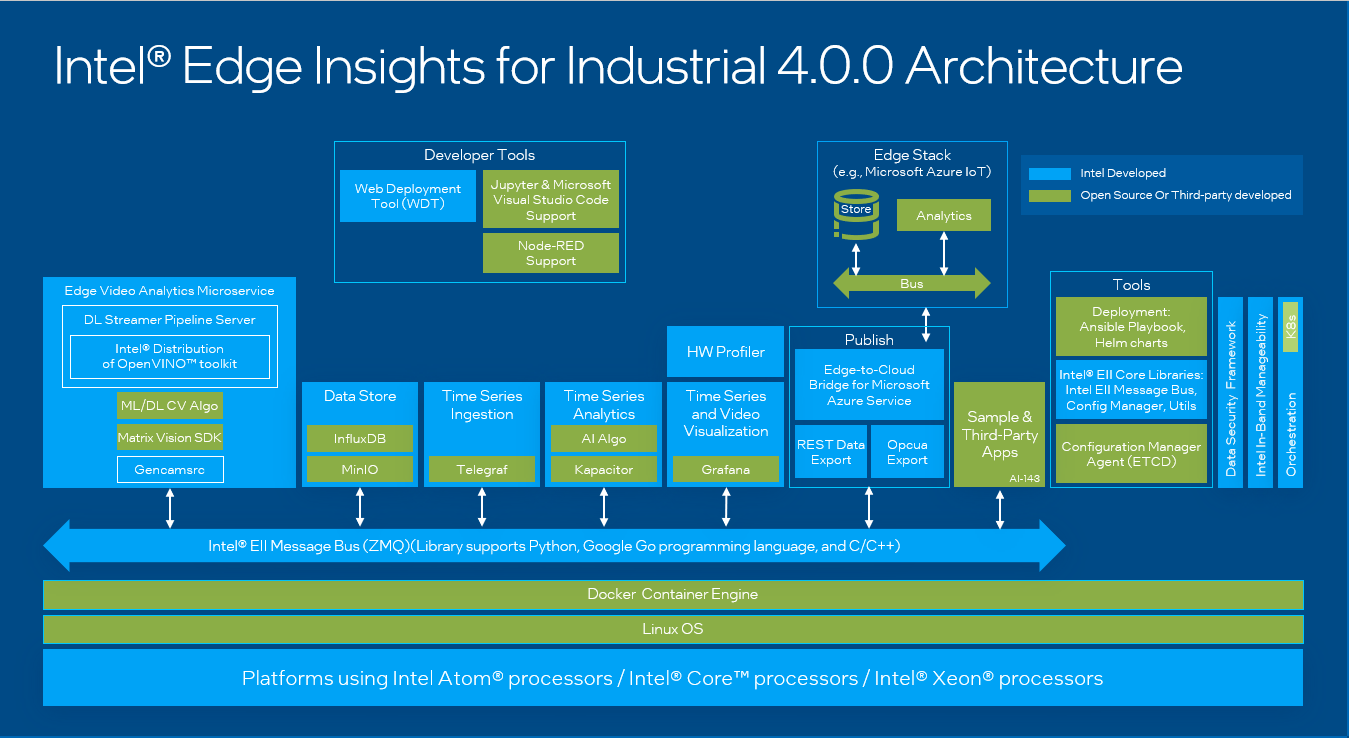

It is best to think about Edge Insights for Industrial (EII) as a set of containers. Figure 2 depicts these containers as dashed lines around the components held by each container. The high-level functions of EII are data ingestion (video and time series), data storage, data analytics, as well as data and device management.

Figure 2. EII Ingredients¶

This EII configuration is designed for deployment near to the site of data generation (for example, a PLC, robotic arm, tool, video camera, sensor, and so on.). The EII Docker* containers perform video and time-series data ingestion, real-time1 analytics, and allow closed-loop control2. The following sections describe how to add new ingestion streams or algorithms within the EII Docker* containers, as well as how the external applications such as a Human Machine Interface (HMI) or a Manufacturing Execution System (MES) connects to EII.

Note

Real-time measurements, as tested by Intel, are as low as 50 milliseconds.

Note

EII closed-loop control functions do not provide deterministic control.